Bonded NdFeB Magnets

Generally, the bonded NdFeB magnet is produced by molding compression of the compound NdFeB alloy powder with epoxy resin, also it can be made by injection or extrusion from NdFeB alloy powder mixed with plastic. The characteristics are as follows:

Generally, the bonded NdFeB magnet is produced by molding compression of the compound NdFeB alloy powder with epoxy resin, also it can be made by injection or extrusion from NdFeB alloy powder mixed with plastic. The characteristics are as follows:

1、Higher Magnet Property: the magnet property of bonded NdFeB magnet is between that of sintered NdFeB and ferrite, and with good consistency and stability.

2、Large Freeness of Product Shapes and High Repumag of Dimension: the magnet shape and dimension are decided by the tooling, like ring, segment, block, etc., without further sintering and mechanical machining processes. 3、Good Corrosion Resistance: after electrodeposited or through other special treatments, it can be used under normal or unfavorable environment conditions for a long time.

4、Diverse magnetization: Multi-pole magnetization and screw angle magnetization are available, and the field distribution could be square, sinusoid and so on.

5、It has high production efficiency, suitable for mass production. The bonded NdFeB magnet is mainly used for all kinds of micro–miniature SMC, such as spindle motor, stepping motor, synchronous motor, DC motor and brushless DC motor. It can replace sintered NdFeB magnet and ferrite, making motor assembling simpler and more reliable, reducing costs and improving efficiency。

Hot Pressed NdFeB Magnets

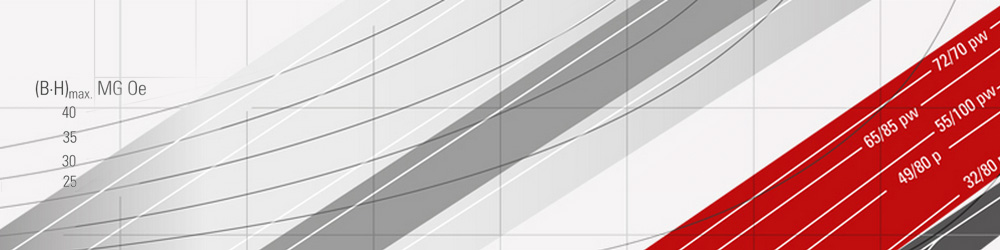

The hot-pressed NdFeB magnets by Chengdu Galaxy Magnets include two types, hot-pressed isotropic NdFeB magnet (MQ2) & hot-extruded anisotropic NdFeB magnet (Mq3).

The hot-pressed NdFeB magnets by Chengdu Galaxy Magnets include two types, hot-pressed isotropic NdFeB magnet (MQ2) & hot-extruded anisotropic NdFeB magnet (Mq3).

The hot-pressed isotropic NdFeB magnet is produced through compression by rapidly quenched NdFeB magnetic powder under high temperature.

The hot-extruded anisotropic NdFeB magnet is mainly anisotropic radially-oriented ring magnet, which is produced through compression and extrusion deformation by rapidly quenched NdFeB magnetic powder under high temperature, with characteristics as the following:

1.High magnetic performance, with the radial maximum magnetic energy product of ring magnet reaching 240~360kJ/m3;

2.The magnet ring is radially-oriented with uniform radial magnetic performance, which can guarantee motor’s silent operation and smooth torque output;

3.High heat-resistance, with working temperature reaching 180℃;

4.The magnetizing poles and pole declination angle of the magnet ring do not have to be reserved, which can be realized through design of changing magnetization coils, with freely using and enough adjustment by customers.

5.The magnetization waves of magnet ring can be customized and magnetized as square wave, sine wave and other special magnetization waves;

6.The magnet ring without assembling can be realized multi-polarization and magnet pole declination, which is convenient for motor assembling;

7.The magnet ring is nanometer crystalline structure with high density and ED coated by epoxy resin with excellent corrosion resistance;

8.The ED coating thickness of epoxy resin can be reached 20~35μm;

The hot-extruded anisotropic radially-oriented ring magnets are mainly applied on EPS SMC, servo SMC, SMC for electric tools and kinds of DC SMC.