NdFeB Magnets

Neodymium magnets can be divided into three main groups:

Neodymium magnets can be divided into three main groups:

1.Regular Neodymium Magnets

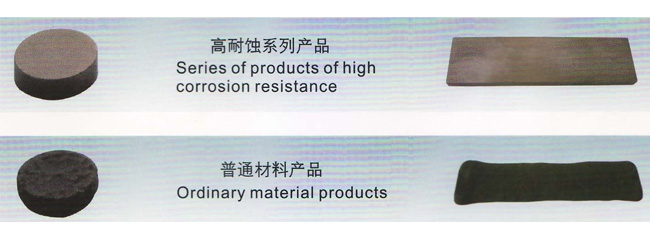

2.High corrosion resistant Neodymium Magnets

3.Bonded Neodymium (Isotropic): Manufactured by the injection of plastic material and Neodymium into a mold. This production method yields a very precise magnet which does not require further grinding and does not suffer substantial current loss.

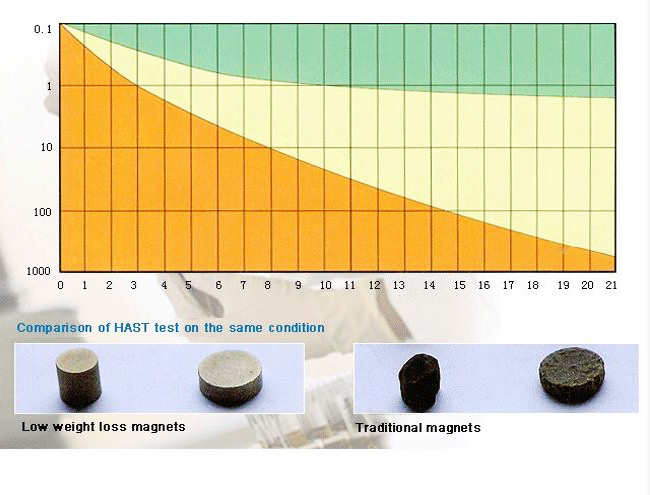

High Corrosion Resistant Magnets

Under the Environment of high temperature, high pressure and high humidity, the weight loss level of uncoated magnets can qualitatively reflect its serving life clearly. Referring to the standard IEC68-2-66 and after 20 days, Hast testing, weight loss of less than 2mg/cm² is available for Repumag, which is the top level worldwide.

Weight loss of Repumag in a Hast-Test ( 130℃, 95% relative humidity 2.7bar in vapor)?

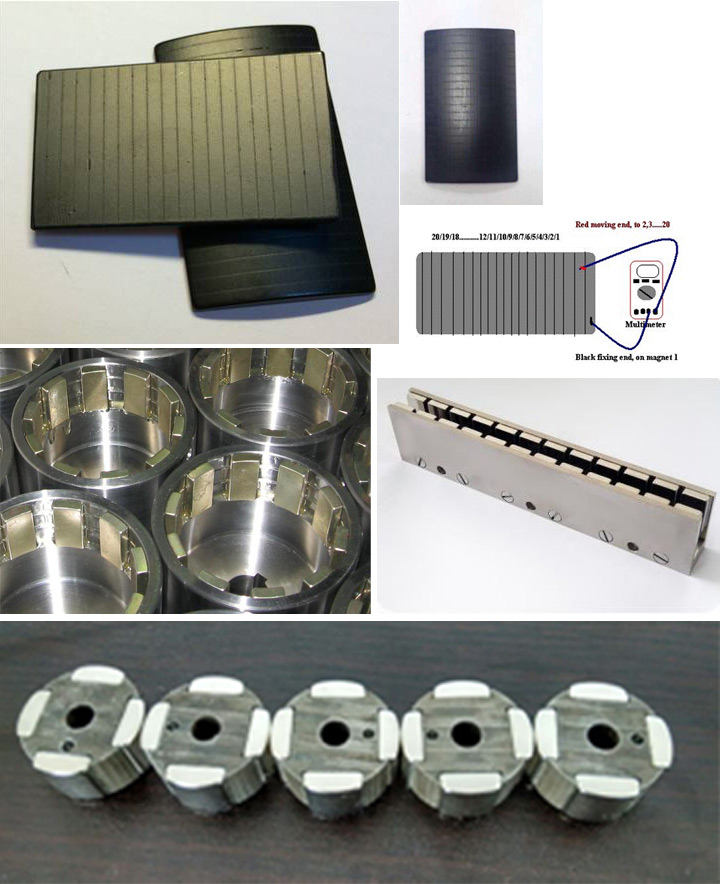

Glued NdFeB Magnets

NdFeB magnets could be glued in any sizes depends on customers requests, there is a max Isolation Resistance requests, glue gap thickness etc, and how to test the isolation resistance as below.

Advantages and Disadvantages

Advantages and Disadvantages of NdFeB Permanent Magnets

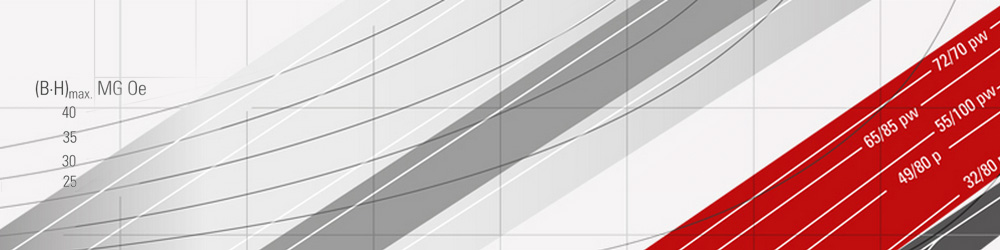

1) Is the strongest magnetic of permanent magnets, has the high energy (BH value) and good coercive force.

2) Manufacturing by the the vacuum sintering process, process maturity;small dimensions,have the good performances and prices; energy (BH value) of NdFeB magnets is more than ten times higher than Ferrites, it is the strongest magnetic materials in the world today, have “magnetic king”reputation.

3) Using the cutting process after sintering,according to the requirements,by the rapid processing, they can be cutted into square,disc.,ring,segment(like tile shape),and so on;Dimension tolerance is commonly +/-0.05mm,if special request,it can be controlled within 0.05mm range by increasing grinding; If requesting the higher process,using the fast quenching scales manufacturing Nd-Fe-B binding NdFeB1988,the repumag of dimensions can be reached 0.01mm,but because the organic binder content cause the low energy product,and the much higher cost of forming dies.

4) NdFeB permanent magnets are easy to be rusted/oxided, so their surface should be done eletroplating treatment, such as galvanized(Zn coating), Nickel+copper+nickel, and so on, generally, it requests more than 48hours in Salt-spray test; also can be passivated treament to slow down its oxidative speed; if using the vacuum plating aluminum + electrophoresis epoxy resin, it can go through more than 96hours in Salt-spray condition.

Comparison Permanent Magnets

Basic Performance Comparison Table of Permanent Magnets

|

Magnets |

BHmax(MGOe) |

Max.Working Temp.(0C) |

Corrosion Resistance |

Magnetic Performance |

Material Price |

Coercive Force |

Processing Charateristics |

Composite Index |

|

Sintered NdFeB |

26-52 |

≤200 |

C |

A+ |

B- |

A+ |

B+ |

70 |

|

SmCo 2:17 |

22-30 |

≤300 |

A |

A |

C- |

A |

C |

64 |

|

SmCo 1: 5 |

16-25 |

≤250 |

A |

A- |

C |

A- |

C |

62 |

|

Bonded NdFeB |

5/12 |

<150 |

B- |

B |

C |

A+ |

- |

68 |

|

AlNiCo |

<10 |

<550 |

A+ |

B |

B |

C- |

C |

54 |

|

Sintered Ferrite |

3-4.5 |

< 350 |

A |

C |

A |

B- |

B |

64 |

|

Bonded Ferrite |

2-3 |

< 150 |

A |

C |

B |

B- |

- |

66 |

|

Rubber |

0.7/1.6 |

<85 |

B |

C |

B+ |

C |

A |

56 |